Water Environment Services

County Administrator Issues/Updates (Virtual) - Feb. 15, 2022

County Administrator Issues/Updates (Virtual) - Feb. 8, 2022

2021 WES Annual Report

Message from the Director

2021 was a pivotal year for Clackamas Water Environment Services (WES).

Greg Geist, Director

Through the ongoing pandemic, a historic ice storm, and an unprecedented heatwave, WES employees worked through these challenges to make sure the services you depend on every day continued without disruption.

We also completed several important projects that strengthen our ability to serve you now and well into the future.

The completion of the Tri-City Solids Handling Improvements Project marks one of the most significant infrastructure milestones for our region in decades. This project ensures the wastewater treatment needs for the nearly 200,000 residents in our service area will be met for generations to come while protecting public health, the environment and future economic growth.

Completion of major upgrades at our nearly 50-year-old Kellogg Creek Water Resource Recovery Facility also helps ensure long-term reliable and affordable treatment services.

Launched in the spring, we initiated a conversation with the community called the Clean Water Exchange to discover what you, our stakeholders, most value related to clean water services, which will help us better serve our district communities.

WES values our customers. We feel privileged to be deeply connected to the cities and neighborhoods we serve, whether it’s partnering on projects or supporting community events.

In addition to approving our lowest monthly rate adjustment in several years, we remain committed to policies and programs designed to help ease financial burdens for customers created by the pandemic.

On behalf of your friends at WES, I wish you all a very happy and healthy 2022.

Greg Geist, Director

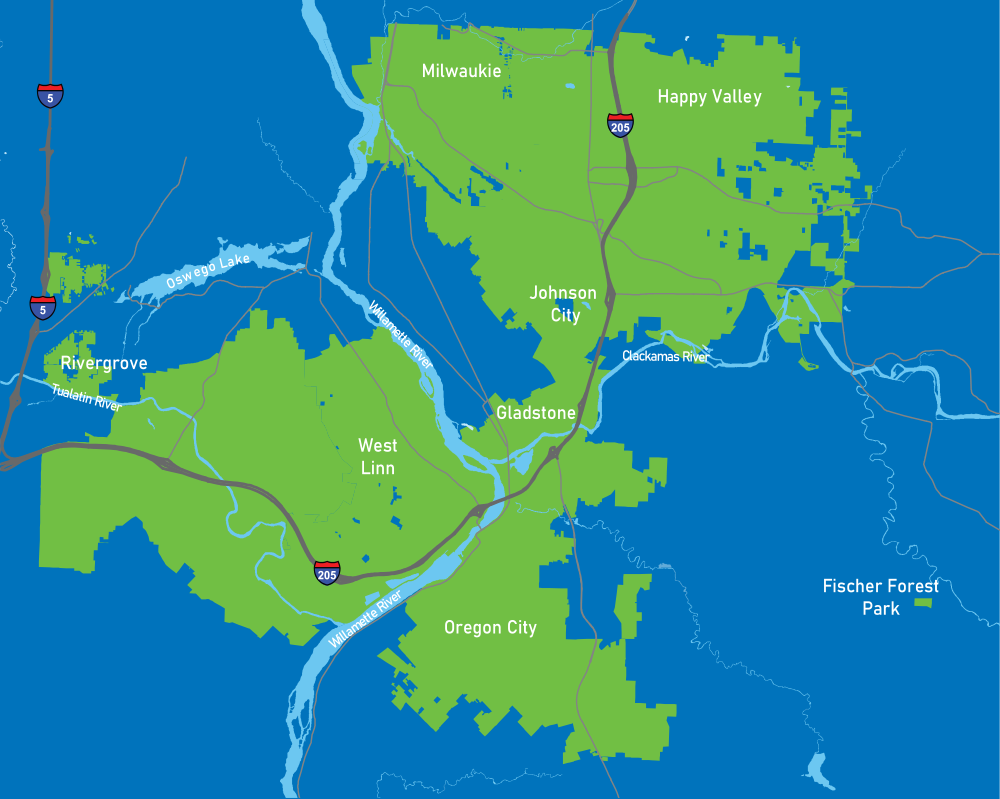

Our Service Area

Clackamas Water Environment Services produces clean water and protects water quality.

We operate and maintain five water resource recovery facilities, 23 pumping stations and more than 360 miles of pipes. Each year, we clean more than seven billion gallons of wastewater, while converting the byproducts of treatment into electricity and natural fertilizer.

We also work to reduce pollution in local rivers, streams and wetlands caused by urban stormwater runoff.

We educate and assist community members from all walks of life, from developers, property managers and homeowners to government agencies, local businesses, teachers and students.

It’s our job to ensure that our community enjoys the benefits of safe, healthy water.

The WES service area includes:

Protecting our Water: Water Heroes

Like you, we will never forget the February ice storm that hit Clackamas County.

During one of the worst ice storms in memory for Clackamas County, WES staff rallied through power loss and icy conditions to maintain wastewater services. WES staff responded to more than 1,000 alarms, working around the clock to keep facilities and pump stations running. During this extraordinary event, there was not a single bypass, sanitary sewer overflow, permit violation, or compliance sample missed. Some WES staff even slept onsite to make sure our equipment kept working.

In October, WES was one of four organizations nationwide to receive the prestigious Water Heroes Award for our work during the ice storm from the Water Environment Federation.

Through the ongoing pandemic, a historic ice storm, and an unprecedented heatwave, WES employees worked through very challenging circumstances to make sure the services you depend on every day continued without disruption. Stewardship doesn’t always

come easy.

Lynne Chicoine Named PNCWA Woman of the Year

Lynne Chicoine, our capital program manager, is hopeful that the 2021 Woman of the Year Award she received from the Pacific Northwest Clean Water Association will inspire more young women and girls to pursue careers in fields where women have historically been underrepresented.

Lynne Chicoine, our capital program manager, is hopeful that the 2021 Woman of the Year Award she received from the Pacific Northwest Clean Water Association will inspire more young women and girls to pursue careers in fields where women have historically been underrepresented.

“This award allows me to serve as an example for young women, whose skills in math and science are matched by their passion for the water environment,” Chicoine said. “The profession, and society broadly, would both benefit if we encouraged and welcomed talented women in technical careers like civil engineering.”

Since 2015, Lynne has led the capital planning and implementation program for WES’ vast wastewater infrastructure.

Despite the ongoing pandemic and other unprecedented challenges, Chicoine led her team to complete or make significant progress on several major WES capital projects in 2021 that will ensure reliable and affordable wastewater treatment services for several decades.

Investing in a Cleaner Future

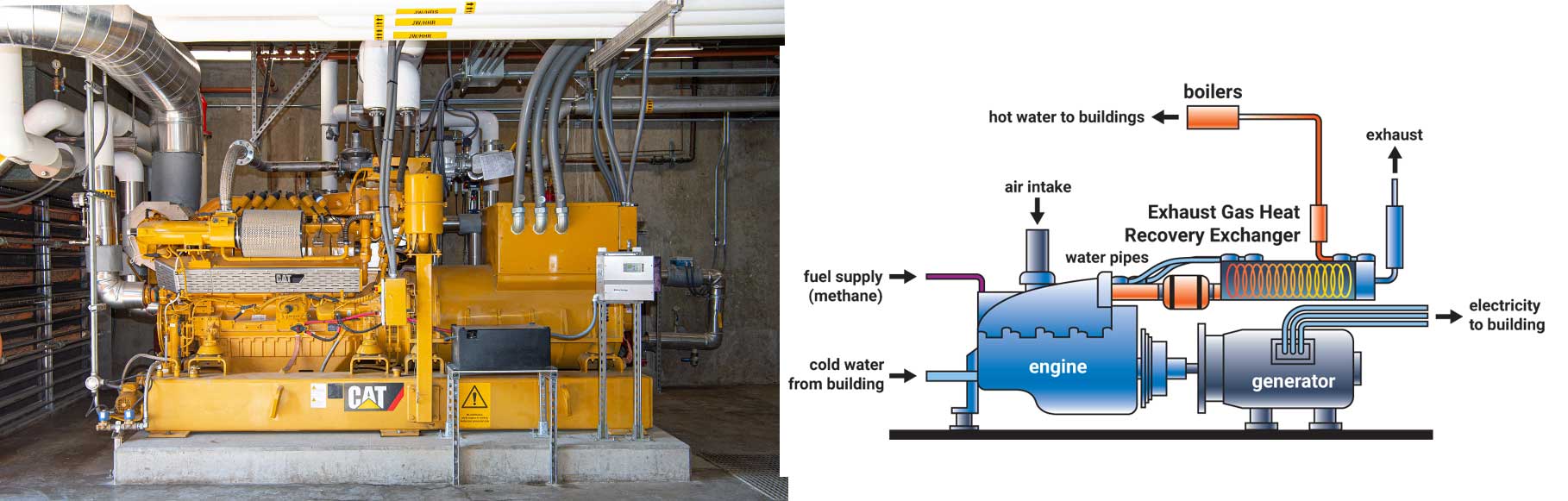

WES’ newly completed Solids Handling Improvements Project will ensure reliable, energy-efficient and affordable wastewater treatment services for generations to come.

The project features a new anaerobic digester to treat solids, a byproduct of waste from homes and businesses.

The upgrade also includes a new co-generation system that transforms organic waste into renewable energy, which produces heat for our Tri-City Water Resource Recovery Facility's buildings and enough electricity to offset nearly half of the facility’s energy use.

Our new co-generation system is made possible with assistance from Energy Trust of Oregon and the Portland General Electric Renewable Development Fund.

As a reminder of the importance of protecting watershed health and in celebration of the completion of the Solids Handling Improvements Project, Artist David Andersen and his Clackamas Community College students created a watershed art mural to educate and inspire visitors.

The new co-generation engine

Portland General Electric Vice President of Public Affairs Dave Robertson, Energy Trust of Oregon Program Manager Dave Moldal, County Commissioner Martha Schrader, State Representative Jeff Reardon, and County Commissioner Paul Savas celebrate the completion of the Solids Handling Improvements Project

Maintaining our Vital Infrastructure

(left) Operations staff inspect the pipes

(right) Field Operators Kevin Rotrock and Otis Lundgren explaining I & I to ratepayers at Happy Valley’s National Night Out

Inflow and Infiltration (I & I) reduction is a top priority for us.

I & I is rainwater or groundwater that seeps into cracked sewer pipes or water that enters pipes through improper connections, and increases the amount of water flow into our wastewater treatment facilities, which puts added strain on equipment.

I & I also increases the risk of sewer overflows.

WES is pursuing a regional approach to solve the I & I problem with our partner cities that own and maintain their own sewer systems, which deliver wastewater to WES’ treatment facilities.

Keeping this extra rainwater and groundwater out of pipes results in significant savings. Reducing I & I by 65% in targeted sub-basins by 2040 would save $120 million in required capital expenditures.

Testing Water Quality for Safety

Our Tri-City Water Quality Lab performs nearly 30,000 analyses per year from each of our facilities to check the health of the water at every step of the wastewater treatment process, making sure the discharge to the Willamette River complies with our permits.

(top) Laboratory Analyst Melissa Catto, (left) Laboratory Analyst Jamie Berger, (right) Source Control Specialist Chris Desiderati brings in samples

Preserving Watershed Health

Watershed health is something we take seriously. We are in the beginning stages of an exciting new floodplain enhancement project and we want your input!

Located near the North Clackamas Aquatic Park in Milwaukie, the 89-acre 3-Creeks Natural Area is where Mt. Scott, Phillips and Dean Creeks converge and provide a special opportunity to restore stream health.

Urbanization is taking a toll on the site, with streams eroding, habitat changing, and flooding of developed properties becoming more common. This project will enhance the floodplain, improve water quality, improve fish and wildlife habitat, and provide opportunities for pedestrian access and environmental education on the site, where feasible.

Protecting the Environment — Surface Water Management

(top) Friends of Trees and Happy Valley Heights team up to plant tree

The Johnson Creek Watershed Council worked with Mad Science to present Science in the Park for children

Our surface water management team provides water quality protection for the communities we serve by implementing programs to reduce pollution in our rivers, streams and wetlands caused by urban stormwater runoff, a leading source of water pollution in our state.

Through watershed protection and planning, WES is taking a long-term approach to protecting the health of our shared water resources.

In 2021, WES awarded $280,523 in grants through our RiverHealth Stewardship Program to 12 organizations dedicated to protecting and improving the health of our watersheds.

Creating Partnerships: The Home Builders Association

(top) Commissioner Martha Schrader poses in front of the WES selfie station at the Street of Dreams

WES’ Natural Resources Scientist Gail Shaloum and Garden Educator Jacob Rose prepare for the Garden Talks presentation

WES teamed up with the Home Builders Association to participate in both the Happy Valley Street of Dreams and the Home of Tomorrow, Today Tour featuring the best in home building sustainability.

WES’ Natural Resources Scientist Gail Shaloum helped organize “Garden Talks” at the Street of Dreams with Garden Educator Jacob Rose to educate attendees about the many environmental benefits of natural gardening and landscaping.

WES also posted several informational signs onsite to educate people about ways they can help protect our environment and sewer system with a few simple steps each day.

This partnership provided WES a unique opportunity to educate more than 20,000 attendees on the subject of watershed health.

Keeping our Waterways Clean with SOLVE

For the fourth consecutive year, WES partnered with SOLVE to keep area waterways and natural areas clean and healthy.

The 2021 Summer Waterway Cleanups in Clackamas County attracted 471 volunteers who helped WES and SOLVE remove thousands of pounds of trash in Clackamas County.

In addition to helping to protect rivers, streams and wildlife, volunteers learn firsthand how trash on the ground can be carried by stormwater runoff into our streams and rivers if not removed.

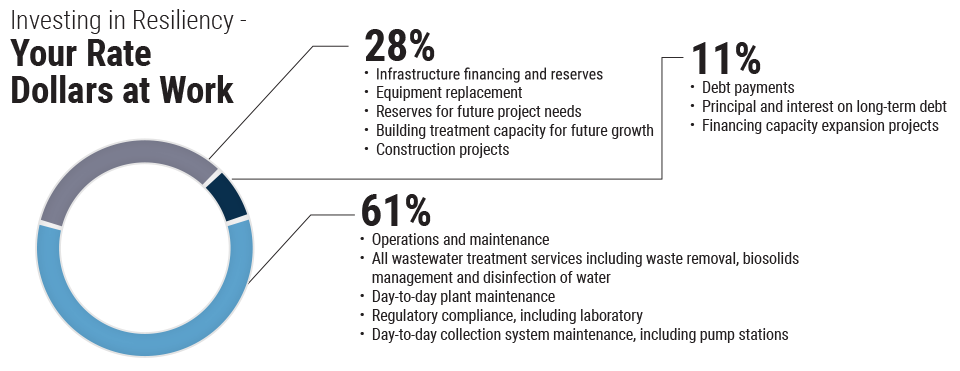

Financial Stewardship

Throughout 2021, WES remained sensitive to the pandemic’s financial impact on many of our customers. To keep monthly bills low, WES approved the lowest annual rate adjustment in many years.

We also remained committed to the suspension of late fees for the duration of the crisis, working with customers on flexible repayment plans based on individual circumstances. We know that every situation is different.

We are heartened to see more customers taking advantage of our low-income discounts for those in need.

Are you managing Your sanitary sewer and surface water account online?

Register for access online to enjoy these features:

- View real-time balances, payment amounts and bill due dates

- Make one-time or recurring payments

- Review transaction history

- Sign up for paperless e-billing to get your bills and our messages emailed to you

Commissioners and Advisory Committee

(left) Advisory Committee member Dr. Renee Harber speaks at the Tri-City WRRF mural celebration

(right) Commissioner Martha Schrader joins the WES team to collect stream insects at the Carli Creek Water Quality Facility

The Clackamas County Board of Commissioners serves as the governing body of WES.

Commissioners receive recommendations from the WES Advisory Committee on a variety of key issues. The WES Advisory Committee includes ratepayers, environmental representatives, business owners, members of the development community and elected officials.

Members have experience in wastewater management, watershed health and restoration, economic development and surface water. The committee provides input and makes recommendations to WES and the Board of County Commissioners.

All WES Advisory Committee members either live or work within the WES

service area.

Clackamas Water Environment Services produces clean water and protects water quality. It’s our job to ensure that residents and visitors enjoy the benefits of safe, healthy water for generations to come.

Thanks for your submission.

Your request has been sent.

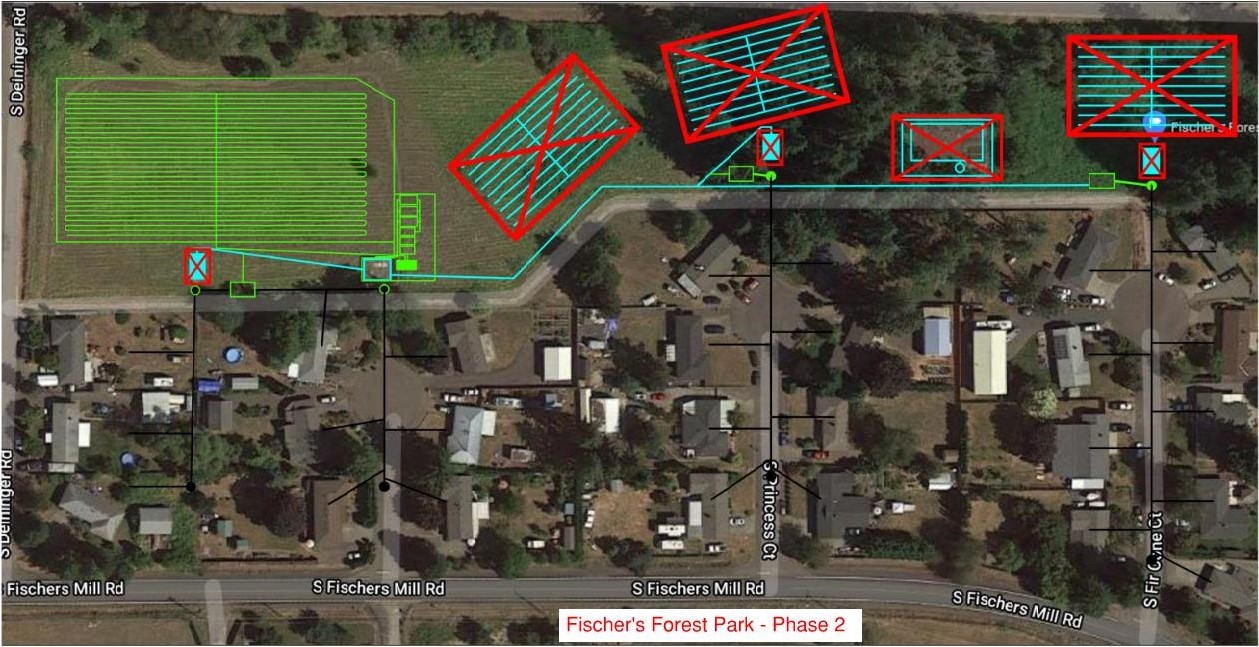

Fischer’s Forest Park Septic System Update – Phase 2

Completed in 2024

Clackamas Water Environment Services (WES) owns and operates the Fischer's Forest Park large onsite septic system (LOSS). The LOSS serves a community consisting of 26 homes on three cul-de-sac streets.

Blue lines: existing facilities

Green lines: new facilities

Red X's: facilities to be decomissions

The original LOSS was installed in the early 1970s, and like any system that is 50 years old, even with routine maintenance, performance deteriorated over time. In 2019, WES hired consultants to complete an evaluation of the collection system (manholes, pipes, septic tanks, recirculation tanks, filtration units, etc.) and the drain fields.

The evaluations identified many deficiencies in the system:

- Some of the pipes had developed sags, and there were areas where pipe connections have separated.

- Several of the concrete structures had cracks that let groundwater into the system, which can cause the system to exceed its treatment capacity.

- Some locations where pipes enter the concrete structures had degraded, allowing groundwater into the system and can cause the system to exceed its treatment capacity.

- Some of the concrete structures and cast iron pipes showed signs of corrosion that could have led to structural failures if left unattended.

- Damage caused by tree roots had left the central drain field severely damaged, and repairing the system in its current location was not realistic option.

- Evidence indicated the east and west drain fields needed to be rehabilitated or replaced.

- The system's operation and distribution controls needed to be modernized to improve the performance and life expectancy of the facility.

Project Accomplishments

- Replaced the entire gravity collection system, including manholes, mainlines, and residential service connections.

- Replaced septic tanks.

- Made improvements to and moved the treatment system to an area north of Merry Meadow Court.

- Created a new drain field

- Decommissioned the old treatment area.

- Fencing: A permanent fence has been added to the project. The new fence has several gates so residents have full access to the field.

- WES has taken over the maintenance of the area inside the fence.

Translate

Translate